Metal

Overview – Stripping Metal

Coopers Stripper penetrates deeply into the old finish, enabling you to remove multiple layers at once. Simply spray on a light application of Coopers Stripper and keep the surface wet with additional stripper until the old finish dissolves sufficiently to expose the metal surface (2~20 minutes), scoop off the gunge, then rinse the metal surface clean with Coopers Flusher, it’s that easy!

Challenges Stripping Metals

Using Coopers has solved many of the problems associated with stripping metal surfaces, for instance it is quite common to cover a stripper, after application, with a plastic sheet, to improve penetration and to slow down evaporation. This adds considerable time and cost to the job as well as a tendency to apply more stripper than is actually needed. Using plastic to cover the stripper is no guarantee all the paint will be ready to come off once the cover is removed.

Corrosion is another problem commonly associated with stripping ferrous metals; many strippers actually recommend rinsing the surface down with water once the stripping is complete, this action will of course promote corrosion, creating further work.

Then off course there’s the biggest problem of all, so many strippers just won’t budge those high performance two packs, oven baked or powder coated finishes.

Project Examples:

- Copper guttering

- Corrugated iron

- Automotive

- Stainless steel tanks

- Powder coated aluminium

- Constructional beams

- Handles, Hinges, Catches and Window stays

Cooper’s Solution / Method

No plastic covering required:

Instead of sitting on the paint surface, like other strippers, where it can evaporate, a light application of Cooper’s Stripper quickly absorbs into the painted surface where it rapidly dissolves the old finish, however, the thicker the paint, the more light applications of stripper that will be needed to dissolve it. Spray application of any additional stripper required makes the whole process quick and easy, without the hassle of all that plastic.

No water used to rinse:

Coopers Flusher is used as a substitute to rinsing the stripped surface with water, Flusher removes any soft residues of both stripper and paint from the metal surface, this leaves the surface clean and dry. Being alcohol based is useful in that it actually removes any moisture from the surface.

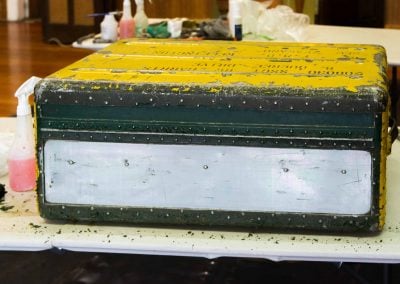

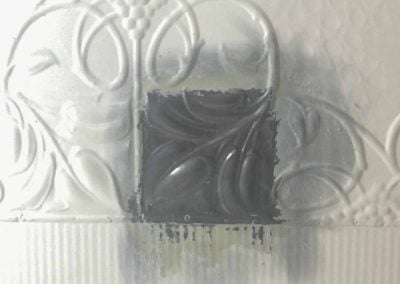

High performance finishes stripped with cooper’s:

The penetrating nature of Cooper’s Stripper makes it ideal for stripping those stubborn hard to remove finishes. Two packs, oven baked, even a powder coated finish will literally delaminate off of the metal.

Tips:

Strip in a shaded area out of the wind

Experiment with the time needed for the stripper to do its job. High performance finishes will take longer than a single pack finish

Mask off, to protect any areas or surfaces not to be stripped

Small items can be soaked in a jar of Stripper until paint is completely softened

What you will need:

- Stripper with spray applicator

- Flusher with spray applicator

- Cooper’s soft copper brush, for detail work (optional)